Does your facility need to perform an Arc Flash Hazard Analysis?

Keep Your Employees Safe From Arc Flash & Shock Hazards

Transworld Electric understands your commitment to following OSHA standards and keeping your employees safe from any electrical hazards. We offer many services in South Carolina and Georgia that help keep your employees’ safe including arc flash hazard analysis, NFPA 70E training, generating facility one-line diagrams, equipment labeling, NFPA 70E compliance and maintenance. Arc flash analysis provides a comprehensive safety analysis, and we’re highly-trained and experienced in arc flash studiesWhat is Arc Flash?

Arc Flash occurs when energized electrical conductors or circuit parts are exposed and ionization of the air occurs or when they are within equipment in a guarded or enclosed condition, provided a person is interacting with the equipment in such a manner that could cause an electric arc. When this happens, the arc faults create large amounts of heat that can severely burn skin, set clothing on fire, and cause hearing loss. At this time, molten metal is blasted from the fault location in a radial direction damaging equipment and resulting potential injury or death.

Under normal operating conditions, enclosed energized equipment that has been properly installed and maintained is not likely to pose an arc flash hazard

Why Should I Perform an Arc Flash Hazard Analysis?

Arc Flash Hazard Analysis is the best way to determine the potential hazard of an arc flash occurs. An Arc Flash Hazard Analysis should be performed periodically and should determine if an arc flash hazard exists. If an arc flash hazard exists, the risk assessment should determine: appropriate safety-related work practices, arc flash boundary, and the proper PPE to be used within the arc flash boundary.

Click here to learn how you can become Arc Flash Compliant using the 6 Point Compliance Checklist.

What is Equipment Labeling?

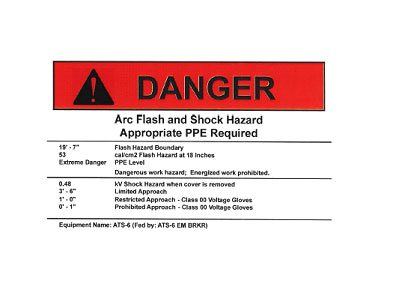

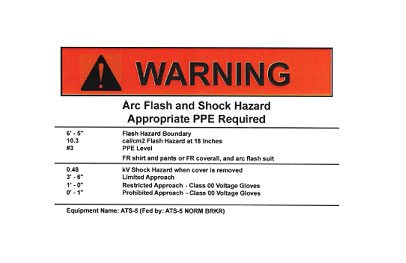

The 2008 NEC Section 110.16 states that electrical equipment likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons that potential of electrical arc flash hazards. According to the NFPA 70E: Standards for Electrical Safety in the Workplace, the Arc Flash Warning Label needs to contain ALL of the following: (1) Nominal System Voltage (2) Arc Flash Boundary (3) At least one of the following (a) Available incident energy and the corresponding working distance or the arc flash PPE category in appropriate tables (b) Minimum Arc Rating of Clothing (c) Site-Specific level of PPE

*The presence of an employee in a work area containing electrical hazards requires the person be “qualified”. Qualified persons are those who have training in avoiding the electrical hazards of working on or near exposed energized parts. Transworld can help you and your employees become a qualified person. Contact us to learn more!*

What if You Must Work on Energized Circuits?

If it has been determined that de-energizing a circuit is not feasible and the employee must work “hot”, the employer shall develop and enforce safety-related work practices to prevent electric shock or other injuries resulting from either direct or indirect electrical contacts.

The specific safety-related work practices shall be consistent with the nature and extent of the associated electrical hazards. [see 1910.333(a)]

- These safety-related work practices could include:

Energized Electrical Work Permit

Personal Protective Equipment

Insulated Tools

Written Safety ProgramFast Fact: The most effective and fool-proof way to eliminate the risk of electrical shock or arc flash is to simply de-energize the equipment.

Does your facility need to perform an Arc Flash Hazard Analysis?

We can make your facility Arc Flash Complaint.

Arc Flash Label Example #1

Arc Flash Label Example #2

Arc Flash AnalysisTyler2022-02-09T14:49:36+00:00